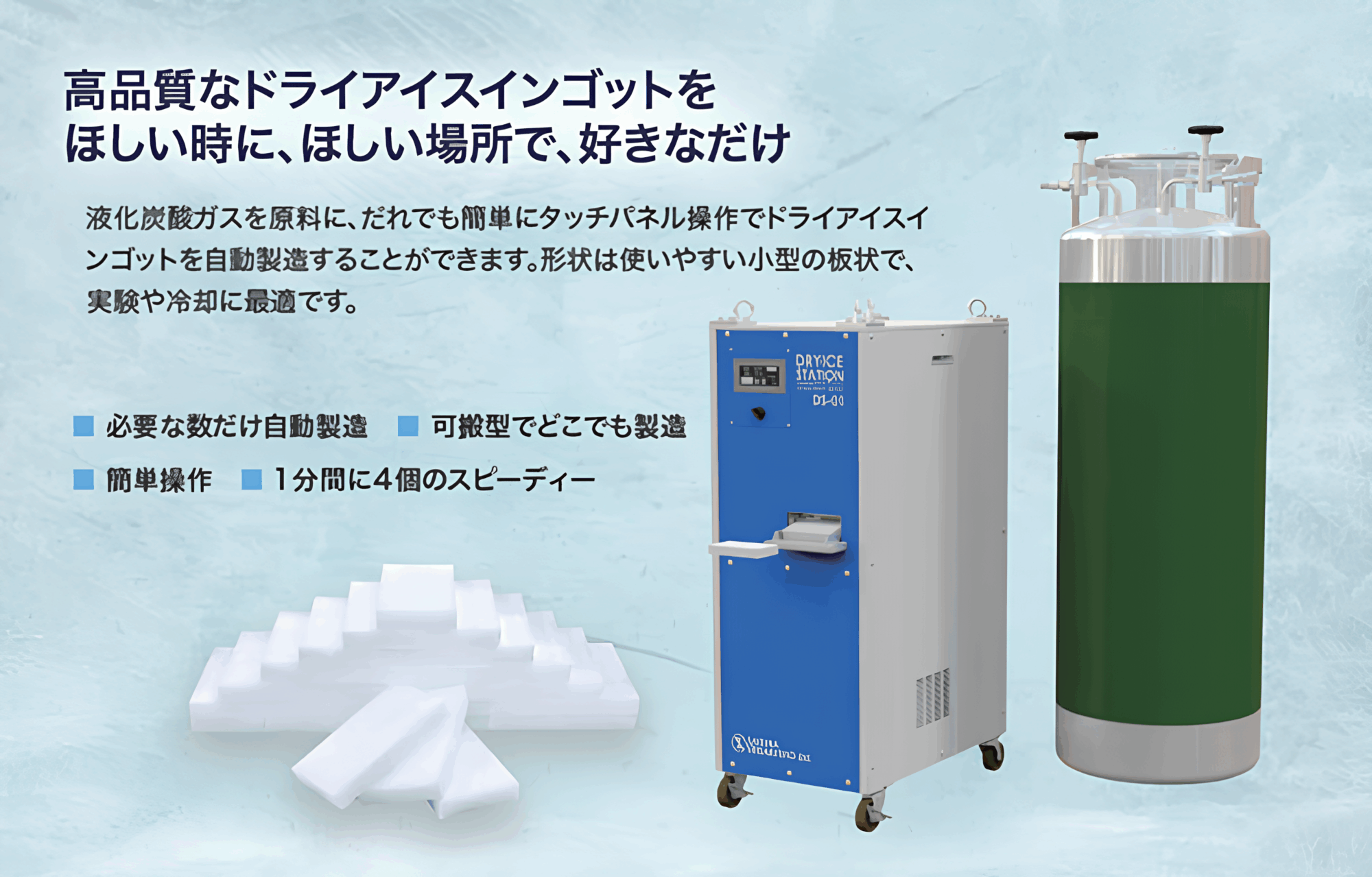

Functions and Features

Key Features

Automatic Production of Dry Ice Ingots from Liquid Carbon Dioxide Gas (Raw Material)

The operation is simplified; by inputting the required quantity, the machine automatically produces Dry Ice Ingots continuously. This eliminates the need to order dry ice from a supplier, accounting for sublimation loss, and allows users to obtain Dry Ice immediately, akin to using a vending machine.

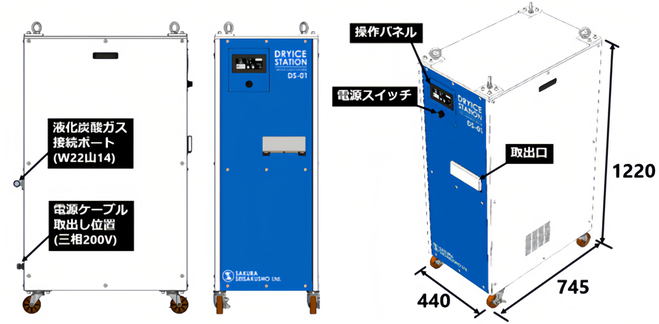

Portable and Ability to Manufacture Anywhere

Equipped with casters, the machine can manufacture Dry Ice on-site, as long as there is a power supply (3-phase 200V) and a Liquid Carbon Dioxide Gas cylinder (LGC container). This reduces sublimation loss during transportation.

High Conversion Economic and Efficiency rate

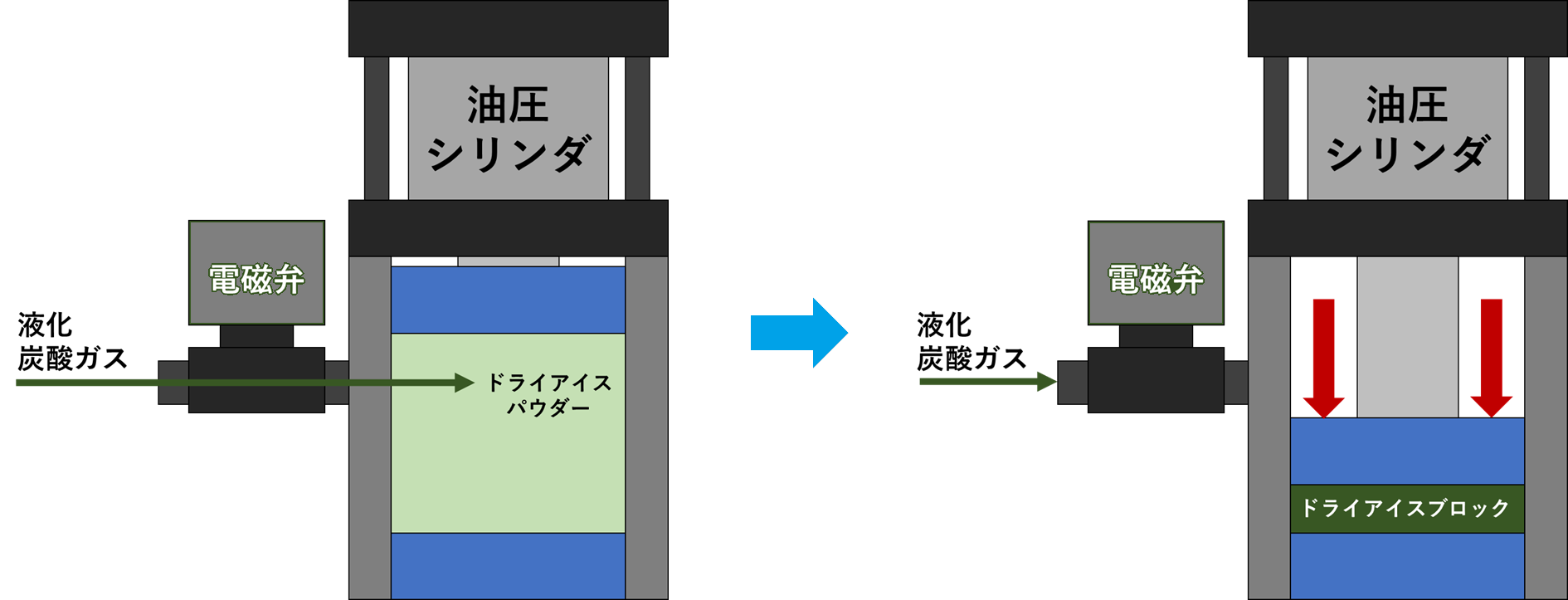

By utilizing Sakura Seisakusho’s unique press mechanism, we have achieved a 44% conversion efficiency rate from Liquid Carbon Dioxide Gas to Dry Ice. This increases the amount of Dry Ice produced per cylinder, making it economically viable. Additionally, manufacturing time is shortened, allowing production of up to 4 ingots per minute.

Dry Ice Ingot and Production Concept

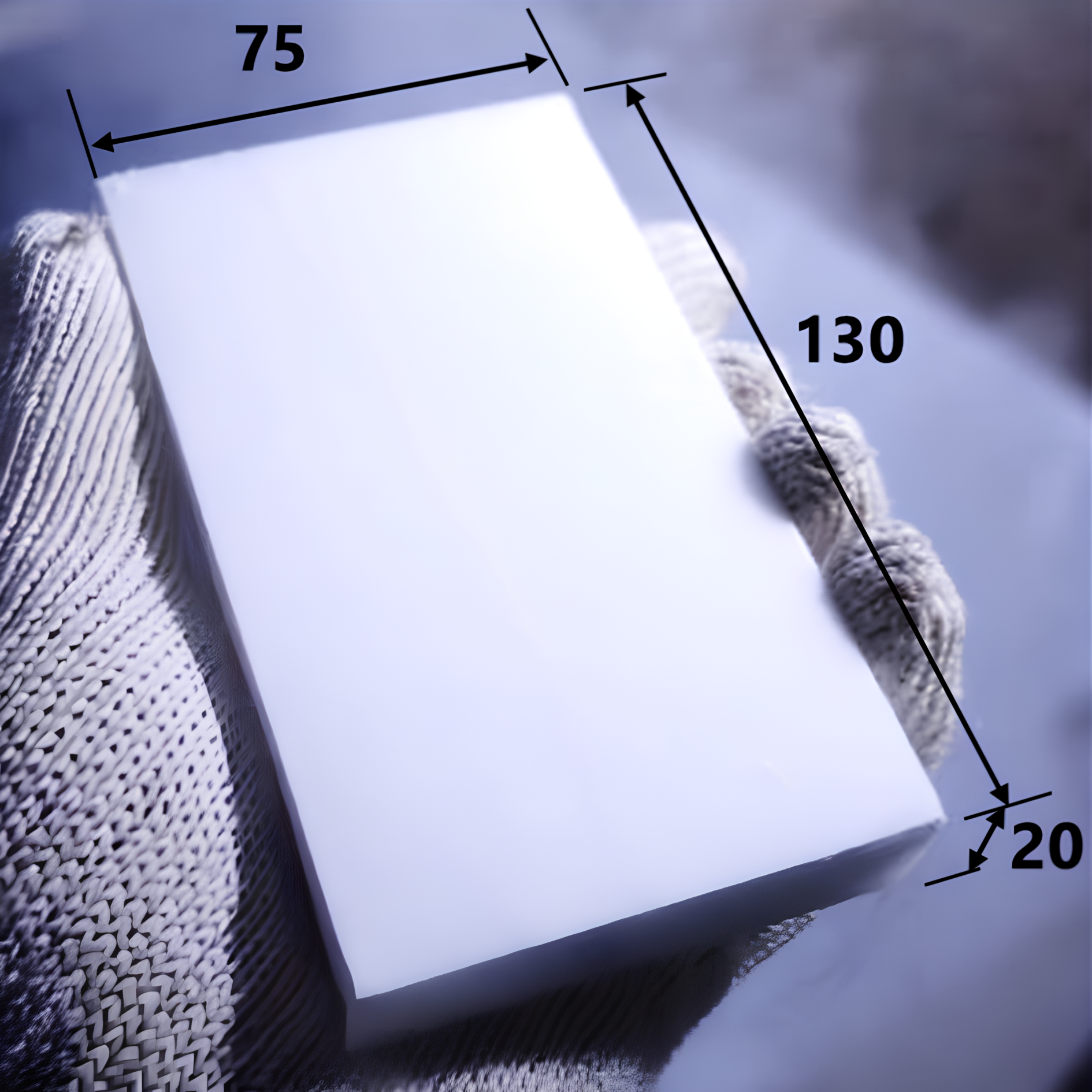

What is a Dry Ice Ingot?

An ingot refers to a bar. The “Dry Ice Ingot” is named to represent easily usable, high-value Dry Ice with excellent cooling performance. Compared to commercially available Dry Ice, Dry Ice Ingots have the following characteristics:

Convenient Shape

Dimensions are 130 × 75 × 20 mm. It features a thin plate shape that can be easily held with one hand, with four corners (rectangular shape). This design prevents unnecessary gaps when lining up in a cooler box or inserting into a cooling vest, efficiently cooling in a wide area. It can also be manually broken and crushed with a hammer to achieve the desired granularity, making it versatile for various cooling applications.

High Density and High Durability (Long Perseverance Time)

With an 11-ton powerful press, it achieves high density equivalent to commercially available dry ice (1.4–1.5 g/cm³). It combines high strength and long durability, ensuring reliable continuous cooling.

-

Principle of Manufacturing Dry Ice Ingots

-

The size of Dry Ice Ingot

-

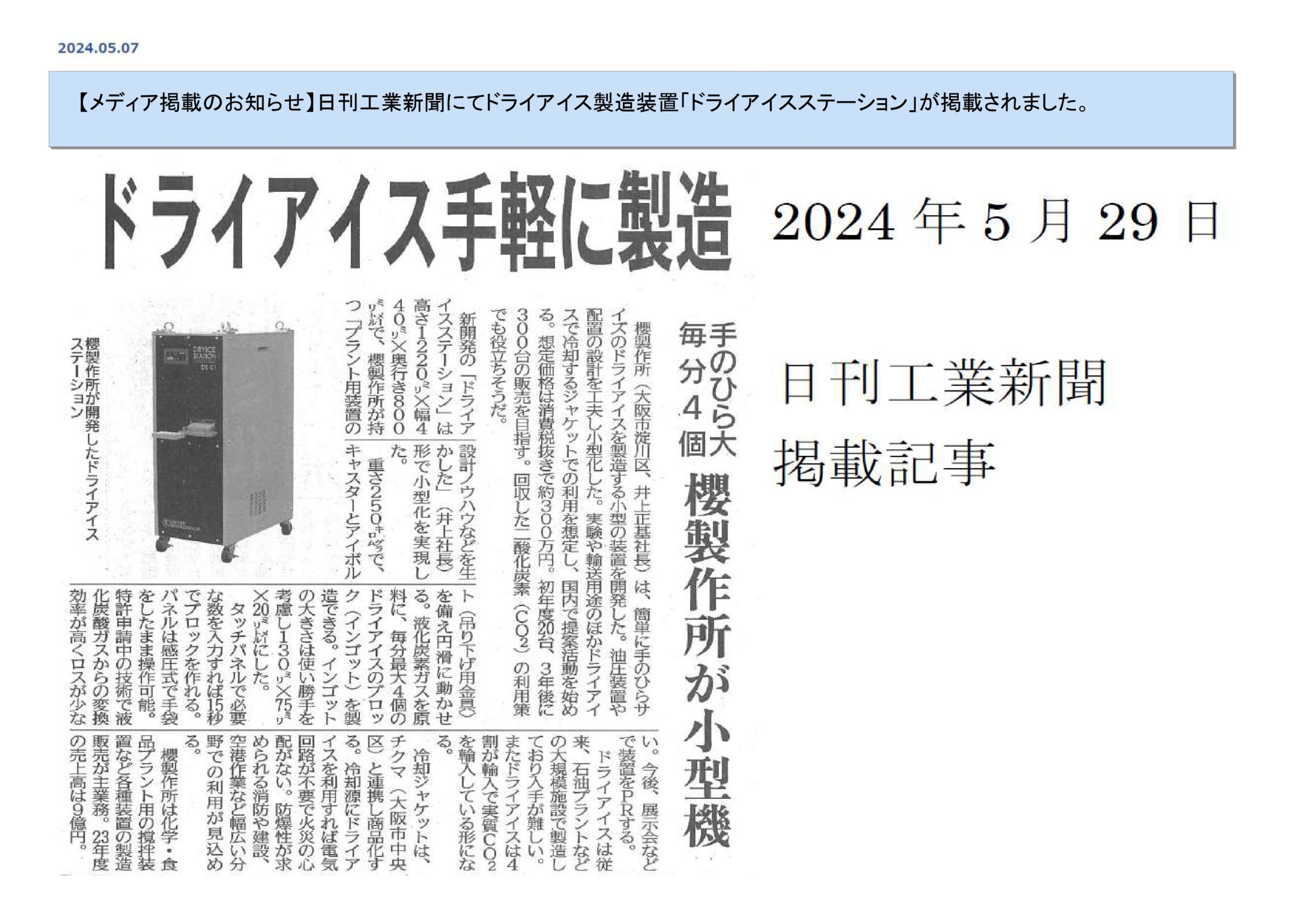

Newspaper in Japan

Field of application

-

Heatstroke Prevention

Applicable for Extreme Heat Environments

-

Low Temperature Shipment

Medical Low Temperature Shipment Fresh Food Transportation

-

Special Usage/ Laboratory

Cryogenic Experiment Medical and Research Laboratory Usage

-

Small Clip of Product Introduction

Small Clip of Operation of Dry Ice Station (JP ver)

Request for quotation

If you would like a quotation for products, please fill in the following Request for Quotation form to the full extent possible.

Our sales representative will contact you soon.